We would like to take this opportunity to thank you for your continued support.

We have been making our utmost efforts to secure parts for maintaining the performance and repair of your machines, and we have been trying to stock these repair parts.

However, it’s been more than 15 years since we launched the machines listed in the attached document, and it has become difficult to obtain repair parts for them because their electrical parts and other components are no longer manufactured by the manufacturer.

As the inventory is getting low and new procurement is not feasible, we would like to inform you that we will discontinue repair services and parts supply for the products listed in the attached document.

We apologize for any inconvenience this may cause to our users and appreciate your understanding in this matter.

Sincerely yours

If you have any questions, please contact your nearest sales office.

Hashima Corporation Gifu Management Center TEL:058-245-4501 FAX:058-247-3366

Tokyo Showroom TEL:03-5793-8400 FAX:03-5793-8434

West Japan Sales Office TEL:072-961-8400 FAX:072-961-8404

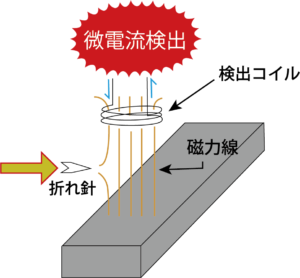

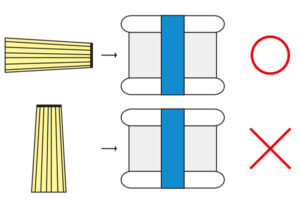

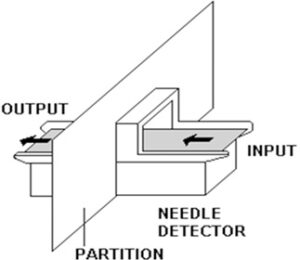

A needle detector is a device that detects magnetic substances (objects that react to magnets) that react to magnetic field lines emitted by magnets by arranging permanent magnets and detection coils in the upper and lower sensor heads.

検出の仕組み

Magnetic lines of force are formed between the permanent magnet and the detection coil in the sensor head.

When a magnetic material such as a broken needle approaches the magnetic field lines, the field lines are deformed. The disturbance is converted into a current value and detected by the detection coil.

The value is converted to a current value, which is detected by the detection coil.

If the value is higher than the sensitivity setting of the needle detector, the conveyor belt stops, rotates in reverse, and sounds an alarm.

Non-magnetic reactions

As mentioned above, basically anything that reacts to magnets can be detected, but in some cases, even nonmagnetic (non-reactive to magnets) materials can be detected.

Nylon-based products such as stockings (petroleum products) and natural animal leather fall into this category.

In some cases, even accessories that are compatible with the needle detector (NC-compatible products) may be detected if they overlap in number or if their surface finish has been cut off, etc. Since even NC-compatible products show a slight reaction, there are cases where detection is made by adding the reaction of the product itself.

In 1994, Hashima manufactured and started sales of its first machine, the HN-600C.

We have developed, manufactured, and sold a variety of needle detectors to meet the demands of each era.

Now (in 2023), the HN-880CS/2880CS are available, but it is becoming difficult to grasp the differences from the machines of the past.

We have compiled a comparison of past conveyor needle detectors in the link below.

List of historical Needle Detector

Sensitivity conversion table

種感度表.jpg)

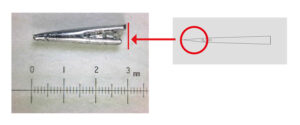

Foreign needle tips are generally broken needles with different sizes, cut surfaces, etc., and their mass is not constant. Therefore, Hashima considers it inappropriate to use needle tip size as a standard for needle detection.

Therefore, Hashima determines machine specifications and performance based on the iron ball equivalent.

The cut surface is not straight and it is difficult to assume mass by length.

Comparison of needlepoint and iron ball mass

The following are the results of mass measurements of needle tips and iron balls at official measuring institutions.

| Iron ball sample name | MASS | NEEDLEPOINT SAMPLE NAME | MASS |

| Fe0.8mm φ | 0.002083g | DB×1 SF No.9? 3mm | 0.002060g |

| DB×1 No. 7? ?3mm | 0.002700g | ||

| DB×1 No. 8? ?3mm | 0.002940g | ||

| Fe1.0mm φ | 0.004063g | DB×1 No. 9? ?3mm | 0.004180g |

| DB×1 No. 11? ?3mm | 0.005160g | ||

| Fe1.2mm φ | 0.007030g | DB×1 No.14? ?3mm | 0.007040g |

| DB×1 No. 16? 3mm | 0.007690g | ||

| Fe1.5mm φ | 0.0137370g |

*Samples were cut at right angles to the needle tip.

As shown in the table, the 3 mm tip of DB×1 SF No. 9 has almost the same mass as the 0.8 mmφ test piece.

Since the test piece and the needle are made of the same components, they are considered to be almost the same in terms of volume.

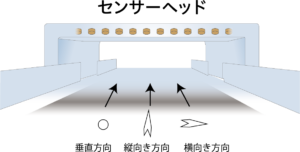

The above is only a comparison of the mass (volume) of the needle tip and the steel ball. The actual folded needle has a longitudinal and a transverse direction to the sensor head, and the detection response differs depending on the direction.

As shown in the figure below, the detection response varies depending on whether the needle tip enters the sensor head vertically, horizontally, or vertically.

Therefore, it is not always possible to detect a foreign object if its mass exceeds that of the test piece.

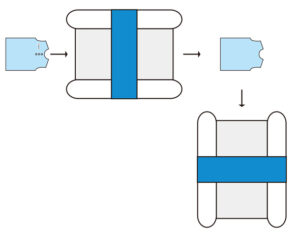

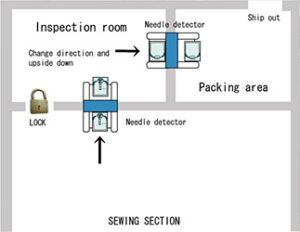

To address this problem, we also offer a device for twice needle detection and a 2-head type needle detector equipped with two heads at different angles.

Twice?needle detection by single?needle detector

Furthermore, if the needle detectors are installed in an L-shape, the directions of the product can be easily changed by 90°.

One-time needle detection by two-head?needle detector

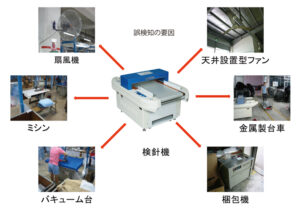

Since the needle detector detects slight disturbances in the magnetic field lines emitted from the permanent magnet, it is greatly affected by vibrations of the machine itself and noise from peripheral equipment. This increases the possibility of false positives.

The above photos show some of the things that can affect the magnetic field of a needle detector and cause false positives.

A needle detection response may occur even though there are no foreign objects such as broken needles mixed in. False positives can also be caused by surrounding environmental factors or by the product itself, in addition to vibration.

Even non-magnetic materials (items that do not react to magnets) may be affected by magnetic fields.

For example, there are reports that petroleum-based materials such as nylon and urethane affect the magnetic field and cause false positives. These reactions are called material effects.

In some cases, these false positives may be in the opposite direction of the iron-based reactions, and in some cases, the reactions may cancel each other out, leading to missing the folded needle that should be detected (false negatives). Therefore, Hashima recommends one-by-one needle detection of the product.

*1 Shedding

The above photos show some of the things that can affect the magnetic field of a meter reader and cause false readings.

A meter reading response may occur even though there are no foreign objects such as broken needles mixed in. False positives can also be caused by surrounding environmental factors or by the product itself, in addition to vibration.

Even non-magnetic materials (items that do not react to magnets) may be affected by magnetic fields.

For example, there are reports that petroleum-based materials such as nylon and urethane affect the magnetic field and cause false detection. These reactions are called material effects.

In some cases, these false positives may be in the opposite direction of the iron-based reactions, and in some cases, the reactions may cancel each other out, leading to missing the folded needle that should be detected. Therefore, Hashima recommends a single-page needle reading of the product.

*One piece at a time

]]>Our test cards/test pieces are manufactured using iron balls manufactured in accordance with JIS standards.

There are two types: a thin card type and a test piece type. Test piece type is affixed to a sponge, which does not affect the magnetic field of the needle detector, and it can be simply placed flat, vertically, horizontally, or at any other height.

The test card type can be inspected by changing the height in 10 mm increments by using a test stand together.

Test cards and test pieces are manufactured and sold in 5 types, Fe0.8mmφ, Fe1.0mmφ, Fe1.2mmφ, Fe 1.5mmφ, and Fe 2.0mmφ.

In recent years, inspection standards have become stricter, and we have heard requests to purchase Fe 0.7mmφ and Fe 0.9mmφ, but Hashima sells only the above five types.

Our needle detector is designed to detect and react to Fe 0.8mmφ and pass Fe0.6mmφ at the sensitivity setting of 10.9. Ideally, we would like to pass Fe 0.7mmφ as well. Still, the difference in reaction between Fe 0.8mmφ and Fe 0.7mmφ is too weak, and if the material reaction in the negative direction mentioned above occurs, the reaction of Fe0.8mmφ may be canceled. The test card may be lost, so a margin is taken. This is the reason for the margin.

Therefore, we do not manufacture or sell test cards of Fe 0.7mmφ or Fe 0.9mmφ.

]]>HN-870CS, HN-780GS, HN-880C/CS, HN-790G/GS, HN-2870CS, HN-2780GS, HN-2880C/CS, and HN-2790G/GS have the? Super Fine mode. This mode allows adjustment of conveyor speed from 40 m/min to 15 m/min in 1 m/min increments.

In recent years, the number of apparel accessories and materials (petroleum-based materials) has been diversifying, increasing the number of products that are detected incorrectly by the inspection machine.

This is partly due to the need to strengthen the needle detection itself (increase the sensitivity level).

Hashima has discovered that the response due to these false positives and the response due to normal magnetic materials varies depending on the belt speed.

Using this, Hashima has made it possible to reduce the conveyor speed in superfine mode and allow accessories to pass through while maintaining the set sensitivity level.

This is not simply a matter of reducing the belt speed.

(*Patented No. 5199725 and 5324818)

Products with no possibility of false positive reactions can still be read with more efficient operation than other companies’ machines with the fast conveyor speed (40 m/min) which is a characteristic of Hashima’s needle detector.

び方-300x269.jpg)

There are windows to hold on the side of the main unit, please hold them to move the machine.

Install the needle detector as far away as possible from the following devices

- fans

- Ceiling-mounted fans

- Sewing machines

- Metal dolly

- Vacuum stand

- Packing machines

Selection of machine installation location

置環(huán)境-1024x802.jpg)

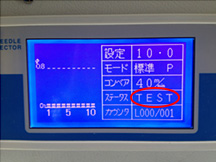

1. Turn on the power while holding down the Up arrow and Enter.

2. Press and hold UP ARROW and ENTER until you hear a small tone.

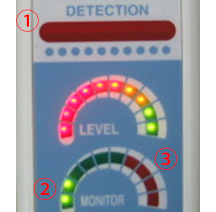

1. Detection position lamp

2. Set the sensitivity setting to 10 and check the response to external noise. If the installation environment is good, the green lamp of MONITOR will light up within 3 lamps.

3. If the red lamp lights up, the installation environment is not good. Move the machine to a new location or move the noise source away from the machine.

Installation of a wall in the needle detection room

?

?

?

?

??

??Clean with a tightly wrung dustcloth.

?

? Protection from dust, etc.

?

?  ?

?  ?

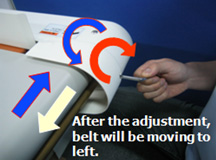

? By turning the inserted wrench clockwise, the belt moves from right to left.

【Notes】

In case of HN-600C, HN-2630C, HN-2650C, HN-2670C HN-2870C, the opposite movement occurs.

?

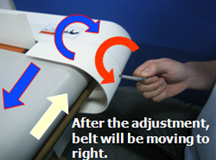

? By turning the inserted wrench counterclockwise, the belt moves from left to right.

【Notes】

If you turn the wrench too far, the belt will move too fast.

Turn the wrench about half a turn, and if the belt starts to move, wait until it comes near the center.

Turn in the opposite direction when the belt is near the center and look for the position where the belt rotates stably.